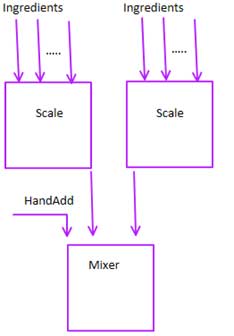

Optimation has just been awarded a batch weighing system for food grade products. The system handles sequencing of different ingredients into a scale and then discharge of the scale into a mixer. These formulations are normally 10 to 12 different ingredients and there are hundreds of different formulations. The typical run size is in tons with approximate 2 tons per batch; therefore 5 to 20 batches of the same formation will be scheduled consecutively.

At this location there are over 20 different ingredient bins and there are “hand adds” that need to be made in certain formulations for “minor” ingredients which are much smaller in volume or other ingredients which are rarely used so are not worthy of dedicating to a bin for a single run. A future upgrade is planned to add a second scale for the “minor” ingredients but still hand adds will be used for the “rarely” used ingredients.

The client had evaluated several specialized systems that are designed to handle weighing of powdered ingredients from bins based on a formulation. Indeed, there are prepackaged solutions for this application. The problem lies in the proliferation of a proprietary solution, the ability for this approach to be used for the entire production line, and its interconnectivity to a production management software for tracking of materials as driven by the Food Safety Modernization Act.

Proprietary solutions are not readily expandable by the user. If an additional bin is required, a new scale is desired, or support of the system is necessary, it may be necessary to go back to the equipment supplier to make relatively simple modifications. If the software is encrypted or the system was designed to handle limited expansions, as is often done to control costs in an OEM package, the opportunity to allow the system to grow is precarious. This was the case in this system. In this particular system, the IO already existed, additional bins were desired, and a future scale was planned. The thought of being “locked” into a configuration was daunting.

In addition, a weighing OEM may not have experience with downstream operations such as grinding, extruding, forming, or packaging. It is a challenge to get each of these functions coordinated under the same control architecture if each specialist is allowed to design to their liking.

Finally, and probably most notably, was DB connectivity to the ERP. There was a need to have the system be SQL friendly. Formulations needed to be queried from the production system and time-stamped, weighing performance information needed to be returned to the it at the end of each batch.

A Rockwell FT Batch system is now being designed to handle these needs. Stay tuned with more to follow on how it all comes together.

{{cta(‘a739d702-5e52-4eda-8613-9997d8548b56’)}}