Rapid Scale-up of Lab Chemistry to Production Scale

Rapid Scale-up of Lab Chemistry to Production Scale

If you have ever interviewed contractors for a remodeling job in your home, you’ve likely heard the age-old quip, “Cheap, Fast, or Perfect, pick 2”. As the phrase indicates, cheap (or shall we say, “palatable price point”) can only be paired with either speed or perfection. You can’t pay low dollars, finish fast and expect a good product. It’s a triangle where one point can never exist in harmony with the other two. If this is true, we can assume that good things will always come to those who wait.

During Q2 of 2022, Dan Curry of Re:Build Optimation gave a talk at the AIChE Conference in San Antonio, TX which tackled the challenge of rapid design and scale-up of chemical processes. The premise of this talk, rooted in three actual cases where scale-up of chemical processes were great successes, was that speed can and should be accomplished AND that both cost and quality do not have to be sacrificed when pursuing speed.

Would you like to know how the Cheap, Fast or Perfect conundrum is solved in a chemical engineers’ world? The clear answer is that Re:Build Optimation and their partners have discovered the new variable that changes everything. Good price structure, speed and quality exist where experts collaborate, even across separate businesses, for a mutual goal. It occurs when these experts sync intentions, energy and even their filing systems to each other for the unrestricted flow of ideas.

The following three case summaries explain, in short, why collaborations have been wildly powerful in rapidly scaling chemical operations.

CASE 1: Solid Waste Processing to Valuable Solid & Liquid Products

Lixivia, experts in organic chemistry based in California required scale-up of waste stream processing to form a new valuable product from a large-scale manufacturing operation in Ohio. Their design partner and Skilled Trades supplier was Re:Build Optimation while GEM acted as General Contractor in Ohio, where this plant would be installed and operated. The original PFD (Process Flow Diagram) was a multi-reactor process where solid waste is processed to separate solids from liquids and convert each into valuable, salable products. The initial design was good – profitable as the numbers go – but we knew we could do better. This is where the magic comes in. Through deep collaboration with our partners, we innovated a single-reactor solution, deleted a costly centrifuge from the original PFD, and got better product output in both quantity and quality! We reduced capital expenditure (fewer reactors, one less centrifuge) and sped up the time to pay off the investment. Additionally, we explored how to operate the system – weekday only versus 24/7. The factors of vessel sizes and the related scale of the associated pumps, piping, valves, etc AND labor were considered. In both cases, weekday only and 24/7 operation, there was a path to profit but in the weekday only application, there was – believe it or not – capability for more product made with less labor!

LESSON: Revisit your designs as a team. Question even the things that work and ask, “Is there a better way?”. The results of one more evaluation of options can be extremely rewarding.

CASE 2: Byogy and the Grass Jet Fuel

It was January 2019 and we got a call. Byogy had innovated a jet-fuel, made from biomaterials. To make a big splash with this product a goal of flying jet airplanes the Japan 2020 Olympics opening ceremonies using ONLY biofuel was set in motion. The partners on this project were Byogy, who are the chemistry experts and innovators of the ethanol based jet fuel, Petron who would design the skid system to convert Ethanol to Ethylene and Re:Build Optimation who would design/build the Ethylene to Jet Fuel skid system.

It was January 2019 and we got a call. Byogy had innovated a jet-fuel, made from biomaterials. To make a big splash with this product a goal of flying jet airplanes the Japan 2020 Olympics opening ceremonies using ONLY biofuel was set in motion. The partners on this project were Byogy, who are the chemistry experts and innovators of the ethanol based jet fuel, Petron who would design the skid system to convert Ethanol to Ethylene and Re:Build Optimation who would design/build the Ethylene to Jet Fuel skid system.

To accomplish this, this trio of companies would have less than one year to design the solution, build, ship AND commission it in Japan. Yes, this skid system was designed and built in the USA and sent to Japan, assembled, and operated in under 12 months. What factors enabled this success?

FACTORS:

- The small, three company team dedicated a set of people from each company to EXCLUSIVELY work on this project. No distractions.

- Key equipment was sourced by Re:Build Optimation – no waiting on customer supplied equipment

- Design for air shipment instead of by sea

- Focus on the details required for design and commissioning the electrically hazardous operation in Japan.

LESSON: Removing distractions helps a team focus. A team with one project, unrestricted from acquiring the needed production equipment, and free to dig deeply into preplanning for details such as safety, regulatory compliance, and even transportation, will be a successful team.

CASE 3: Organic, Intermediate Product Manufacture on Continuous Skid

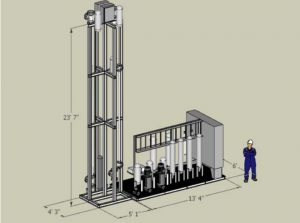

Once again, three clients, including us here at Re:Build Optimation, working as a team to innovate a very tall skid based system. We’re about to begin the detail engineering for this project right now and there are two key takeaways we can share at this point

As we estimate project costs associated with the P&ID we have created, we use spreadsheets which allow us to explore every dimension of the potential design. With pricing from our vendors input, plus our tradespeople inputting labor estimates, we can spec out multiple parts and subsystems in which we can both estimate a system AND choose to do the thought exercise of removing parts and replacing them with others. The spreadsheet can allow us to evaluate options effectively and give us clarity and confidence that the different parts of the estimate make sense.

The second key takeaway is about data flow. Through the use of Microsoft Teams we have an open document flow, which is fully tracked for all changes and updates, so that all parties have full access. There are no silos, there is no waiting for details. We share EVERYTHING so we can really work as a team. Yes, we’re different businesses, but we’re all on the same team. This transparency is about speed, it’s about trust, and is full of great potential.

That old maxim, “Cheap, Fast or Perfect, pick 2” doesn’t hold weight in our world. Fair priced, Speedy, and Powerful all can be had provided that Expert Teams are given the permission to band together and do what they know can be done.