Alternative Energy Automation

Alternative Energy Automation

Since our founding in 1985, the goal of Optimation Technology has been to provide our clients with manufacturing solutions from start to finish. Whether it’s a simple maintenance service or a full-scale industrial project, our designers, engineers, and skilled tradespeople provide the technical and industrial expertise to support our clients in the future of their manufacturing.

Renewable energy sources, such as hydrogen, biomass, wind, and solar energy have been a main focus in response to growing demands for sustainability power. At Optimation, we aid in this movement with the development and deployment of fuel cells, biofuel, wind power systems, and solar cells. Batteries and other renewable energy storage forms are a significant part of Optimation’s business.

Biofuels as Alternative Fuels

Biofuels, such as ethanol, are alternative fuels derived from plant matter. Biofuels offer a renewable energy resource that can often replace fossil fuels. With growing concerns regarding fossil fuel shortages and negative environmental effects, there has been an increasing focus on the production of sustainable, maintainable sources that we can harvest and invest in.

An example of the movement towards biofuels, Optimation helped engineer, design and construct cellulose-based ethanol development and production systems. Our construction experience, process automation and chemical engineering expertise, and our fabrication facilities make us a great resource as new enzymes and feedstocks continue to be developed. As companies require plant modifications and upgrades systems such as these can provide the clean power our society needs.

By working with us for your biofuel development and production project, you’ll see benefits such as:

- Enhanced control of ingredient additions

- Faster and higher quality production with less complexity and lower costs

- Increased reliability and repeatability

- Assistance from concept through completion, including functional specification, testing, implementation, and process deployment

- Fast-track design and installation

Hydrogen Energy – Fuel Cells

The most abundant element in the universe, hydrogen, is available for us in many ways. There are different fuel cell technologies such as Proton Exchange Membrane, Solid Oxide, and others. Each has features that suit them for certain applications. Generally speaking, the world is looking to hydrogen fuel cells to power vehicles, from fork trucks to cars to over-the-road trucks, and even planes and ships.

This tremendous scientific marvel offers green energy by reforming other fuel types and via a chemical reaction within the system, produces the desired electricity and other benign by-products such as heat and water. The cost of fuel cells is decreasing as their uses increase. While they were once the domain of the scientist and astronaut (fuel cells took humans to the moon, along with a healthy load of liquid oxygen). Now engineers are putting fuel cells to work in so many different applications, and still mission-critical in space work.

Besides those mentioned earlier, fuel cells are used in stationary applications, such as back-up power for hospitals and data centers, and remote locations that are not on the grid. Optimation’s deep and broad experience in fuel cell assembly, test, and startup work give us a perspective and experience base that is unique, especially in our abilities to design, fabricate, and deploy from start to finish all under one roof.

Alternative Energy – Wind

Wind farms are used all over the world to produce electricity on a large scale. Industry leaders like GE are continuously working to innovate wind energy sources and make turbines and supporting infrastructure more efficient, environmentally friendly, and cost-effective. To do so, GE Renewable Energy’s Additive Manufacturing is using huge 3D printers to print concrete bases on-site to support skyscraper-sized wind turbines.

Optimation is supporting this initiative by engineering the necessary equipment and providing support for the printing process. Taller turbines with larger blades can reach winds at higher altitudes and generate more power. However, these large structures present certain logistical challenges. To meet these challenges, Optimation is working with GE to print turbine bases directly at each wind farm, resulting in several financial, environmental, logistical, and technical benefits.

Our experts support this project by:

- Providing structural analysis of the 3D printer frame to ensure compliance with regulations and safety codes

- Developing engineering specifications for the mixing equipment and concrete batch plant

- Integrating the specifications into the 3D printing system

- Providing any necessary engineering and fabrication work

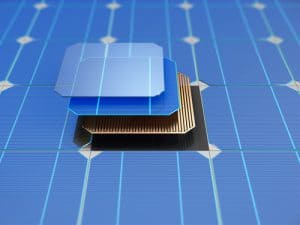

Solar Cells

Solar cells work by converting light energy to electricity. This provides a cost-effective, environmentally friendly power source. These devices are often produced using roll-to-roll processing, a developing technology aimed at decreasing the cost of conventional semiconductor manufacturing techniques.

Optimation’s web coating, handling, and converting experience combined with our media conveyance facility (MCF) make us the ideal partner for development and prototyping needs. Our skills enable us to help design and implement large-scale solar energy manufacturing facilities while maintaining low costs.

Some of our MCF capabilities include:

- Internal and surface-level defect detection, tracking, and elimination

- Web handling and multiple thin-layer coating equipment expertise

- Optimization of knurling, winding, slitting, tension, and conveyance

- Consistent shrinkage, planarity, and roll-to-roll oriented web crystallinity/DSC

Why Optimation?

Optimation welcomes the challenges of producing renewable energy sources, and we’re ready to offer energy solutions at every stage of the process up to full-scale production. With extensive knowledge in chemical engineering and process automation, we can be a key contributor to the sustainable energy movement. Through flexible problem solving, testing of process techniques, and evaluation, we can work with clients to successfully implement alternative energy projects.

For more information about our renewable energy capabilities and solutions, contact the experts at Optimation today.